Expert Metal Fabrication for OEMs Who Demand More

Laser cutting. Forming. Welding. Assembly. One trusted partner.

We're proud to supply parts that go into some of the most trusted systems in the world.

Contract Manufacturing

You Can Count On

At LMI Manufacturing, we deliver metal fabrication solutions that keep OEM operations running smoothly. Our team produces precision-engineered metal components all under one roof. Whether you need tight-tolerance prototypes or repeat production runs, our manufacturing services provide consistent quality, faster lead times, and unmatched reliability.

Estimating & pre-quote feasibility procedure

Customer onboarding & monitoring

Sub-supplier management

On-time delivery tracking

PPM

Monitoring

We Fix What's Holding You Back

We are experts in processing and developing solutions to solve your production problems.

Fast ramp-up

for production

We reserve production capacity for urgent projects, helping OEMs hit critical launch dates without sacrificing quality.

Improve Lead

Times

Our streamlined metal fabrication services for low- and mid-volume runs minimize production delays, accelerate turnaround, and help you meet tight deadlines.

Better

Quality

Tired of Rework and Inconsistency? With certified welders, quality management software, and detailed inspections, we deliver parts that meet your specs consistently.

Reduced

Costs

Our ability to cut, form, weld, and assemble in-house means fewer markups, faster turnarounds, and leaner project costs.

Our Core Metal

Fabrication Capabilities

Everything you need.

All under one roof.

We don’t farm out the hard stuff - we built a team and a facility to handle it ourselves. That means shorter lead times, fewer headaches, and more reliable results for OEMs nationwide.

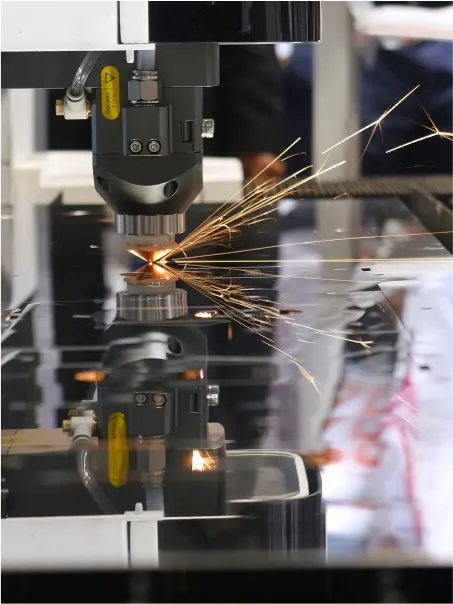

Laser Cutting

High-speed 6kW fiber laser cutting for sheet sizes up to 79" × 158", delivering tight tolerances, clean edges, and superb repeatability for complex parts and OEM needs.

Metal Forming

Offline-programmed press brake forming with a broad tooling library for precise bends, dependable repeatability, and efficient setup — ideal for low- to mid-volume metal parts manufacturing.

Welding

Manual and robotic welding performed by certified pros — qualified up to 1" thick — for clean, consistent welds on complex weldments.

Machining

Tight-tolerance machining (milling and turning) integrated with fabrication for fewer setups, better accuracy, and faster throughput from prototype to production.

Assembly

Turnkey assembly for subassemblies and component integration — all in-house for shorter lead times, lower total cost, and stronger QA traceability.

Industries We Serve

Built for precision and performance in high-demand environments.

LMI supports a wide range of OEMs across industries. We deliver metal fabrication solutions engineered for speed, accuracy, and long-term reliability. Whether you need custom metal fabrication or full contract manufacturing, our team ensures every part meets your performance standards.

Agriculture & Dirt Movement

Structural weldments and framework for soil prep and irrigation

Why OEMs Choose LMI for Metal Fabrication Solutions

Smart Fabrication. Transparent Process. Real Results.

When you're under pressure to deliver—whether for a build, a PO, or a production ramp—we're the supplier that shows up and makes it happen. We combine experience, technology, and clear communication to keep your projects on schedule — every time.

Fast Quotes

80% of metal fabrication quotes turned around in under 48 hours

Consistent Quality

Certified welds, QA tracking, and production repeatability

In-House Control

Laser to weld to assembly,

managed start to finish

Proven Track Record

Trusted by OEMs for 60+ years

of industrial fabrication excellence

People You Can Reach

Get answers, updates, and real communication when you need it

Emergency Flex

20% of capacity reserved for rush jobs when timelines are tight

Partnering with LMI means fewer emails, fewer

issues, and fewer delays.

Explore Our Metal Fabrication Facility

40,000 sq. ft. of advanced metal fabrication power in Hartford, Wisconsin

With the equipment, space, and staff to handle jobs big and small, our facility gives you the edge when you need repeatable quality and shorter lead times.

- Robotic welding cells

- 6kW fiber laser (79” x 158”)

- CNC machining centers

- Precision press brakes

- In-house assembly & staging areas

Our Custom Metal Fabrication Process

Every project at LMI follows a proven process designed for precision and efficiency:

- Quote & Consultation: Send your SolidWorks files — most quotes are returned within 24–48 hours.

- Prototyping (Optional): We assist with prototypes that transition seamlessly into production for mid- to large- volume runs.

- Fabrication: In-house laser cutting, metal forming, welding, and machining performed by skilled fabricators.

- Assembly & QA: We complete all assembly and quality inspections under one roof for traceability.

- Delivery: Reliable lead times (2–3 weeks average), with rush capacity available when you need it.

The result: consistent metal parts manufacturing that meets your exact specifications — every time.

The Value of In-House Metal Fabrication

In-house metal fabrication streamlines production by keeping every step under one roof, from laser cutting and metal forming to welding, machining, and assembly.

When critical processes stay connected, projects move faster, communication stays clear, and quality stays consistent from start to finish.

For OEMs, this means greater control over timelines, costs, and part performance—key advantages that drive repeatable, high-quality results in every production run.

Latest From The LMI Blog

Insights, updates, and fabrication best practices.

How Supply Chain Disruptions Are Changing OEM Expectations

Cascading shocks—tariffs, logistics swings, labor gaps, and cyber events—have pushed OEMs to rebalance cost against...

Read MoreMeet Our New Robotic Welder: Consistency Up, Strain Down

At LMI, we’ve added a Lincoln collaborative robot welder with a 72" reach to our...

Read MoreLMI Achieves ISO-9001 Certification

What It Means for Our Customers At LMI Manufacturing, quality has always been at the...

Read MoreReady to Work With a Metal Fabricator Who Gets It Done?

We’re built for speed. Tuned for precision. And driven by long-term partnerships, not one-off transactions.

Let’s make something better - together.

Metal Fabrication Services Frequently Asked Questions

We work with carbon steel, stainless steel, aluminum, copper, and brass—cut, formed, welded, and machined to your exact specifications. Our metal fabrication services deliver the strength, precision, and long-term performance required for demanding production applications.

Standard lead times are 2–3 weeks, depending on project complexity. We also reserve 20% of our production capacity for rush jobs and can turn most quotes within 24–48 hours to keep your production on schedule.

We support prototypes as long as they are part of a project associated with a recurring production run. The core of our business is in recurring mid-volume production–especially when precision and repeatability are key.

Absolutely. While finishing is outsourced to trusted local partners, LMI manages coordination, inspection, and delivery to ensure every part meets our strict quality standards. You’ll receive a complete metal fabrication solution from start to finish.

We keep nearly every process in-house—from laser cutting and metal forming to welding, machining, and assembly. This allows us to prioritize communication, reduce lead times, and ensure consistent quality that OEMs have trusted for more than 60 years.

Our core capabilities include:

- Laser cutting with a 6kW fiber laser (up to 79" × 158")

- Press brake forming with precision tooling

- Manual and robotic welding, certified up to 1" thick

- CNC machining for tight-tolerance components

- Turnkey assembly and subassembly integration

All performed under one roof for better efficiency and quality control.

Yes — LMI Manufacturing is ISO 9001:2015 Certified, ensuring consistent quality management and traceability throughout every stage of production.

Yes. While our 40,000 sq. ft. facility is based in Hartford, Wisconsin, we serve OEMs nationwide, particularly across the Midwest and South. Our streamlined logistics and communication make us a reliable partner wherever you operate.

In many cases, yes. By performing laser cutting, forming, welding, machining, and assembly in-house, we eliminate unnecessary markups and delays. This integrated approach often leads to leaner project costs, faster delivery, and greater process control for your team.

We partner with OEMs in electrical and power distribution, food processing, material handling, agriculture, data centers, and industrial machinery—industries that demand precise, reliable, and repeatable metal parts manufacturing.

Yes. LMI provides custom metal fabrication for mid-volume production runs and contract manufacturing for recurring projects. Our flexible approach helps OEMs scale efficiently while maintaining consistent quality and reliable turnaround times.